Dennis Energy Services, Inc.

Laredo, TX | Fort Worth, TX | Shreveport, LA | Odessa, TX

toll free: 1-888-712-5595

fax: 956-712-4788

DESI GST™ Drilling Beads

View Material Safety Data Sheet

Running Procedure: Reduction of Torque and Drag or Covering Lateral Prior to Running Casing

-

Blend 8 to 10 PPB of DESI GST Drilling beads in a 30 to 50 Barrel pill.

*Coverage area required: Top of curve to BHTD for desired pill size to be prepared. NOTE: Before opening valve to begin pumping pill, take appropriate measures to ensure that the pit suction is cleared of product build up to be certain there is not an initial heavy slug of product heavier that intended PPB ratio.

Pull off of bottom 10 to 20 feet and begin rotating 20 to 30 RPMs while pumping GST Bead sweep. DO NOT ATTEMPT TO SLIDE WHILE PUMPING BEAD SWEEP.

To displace beads throughout hole section once pill is displaced through bit, shut down pumps, reciprocate pipe, and continue slow rotating (as hole conditions dictate) to work beads into wellbore wall, while monitoring torque and drag.

Continue to bottom and continue to drill, sliding according to established drilling procedures. 30 barrel sweeps may be used to cover new open hole when torque or drag rates elevate.

Follow above procedures to repeat pumping of all beads pills.

For Reduction of Torque and Drag and Prevention of Differential Sticking

-

The problems found in both vertical and directional holes are friction, key seating (repeated drill string contact with casing and bore hole), and differential sticking. These problems may occur in the following areas:

- Low side of the horizontal (lateral) section

- Deviations from vertical to lateral

-

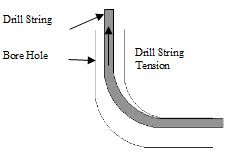

Figure 1: Drill string in tension (while picking up)

-

Figure 2: Drill string in compression (while slacking off)

-

Figure 1: Drill string in tension (while picking up)

- Deviations in vertical drilling

- Porous formations (differential sticking)

- DESI GST™ Beads (View Comparison Chart) are an excellent solution to reduce friction, key seating, and differential sticking based on the following characteristics.

- Composition: DESI GST™ Beads neither affect, nor are affected by, mud chemistry. Glass Beads share this characteristic but Plastic Beads mostly do so only in water based muds. DESI GST™ Beads retain their shape under pressure and stand up well to the hydrocarbon environment. Plastic Beads on the other hand more easily deform (increasing friction) and decompose (adversely affecting mud chemistry).

- Specific Gravity: DESI GST™ Beads are by far the heaviest of the beads. With a specific gravity of 3.2, DESI GST™ Beads have more tendency to migrate to the low side of a lateral or deviated hole. They also have the tendency to stay in the hole and are less likely to be circulated out and over the shaker, thus removing them from the system. DESI GST™ Beads remain negatively buoyant in muds up to 26.5 ppg where Plastic Beads are neutrally buoyant in muds at only 8.33 ppg. DESI GST™ Bead affords the operator the benefit of buying fewer beads to relieve torque and drag simply because these beads stay in the hole where they can do their work.

- Crush Resistance: The DESI GST™ Bead is the strongest of the beads. This characteristic qualifies DESI GST™ Bead to withstand the weight of the bottom hole assembly and drill pipe. DESI GST™ Bead's strength also enables it to maintain structural integrity in order to prevent or break the bond of pipe against the wall of the open hole and/or casing.

- Screen Analysis: DESI GST™ Drilling Beads range is size between 30 and 60 mesh. This size range promotes the movement of beads to the contact side of the drill string—small beads first easing the way for progressively larger ones.

- Roundness: DESI GST™ Beads are the most round of the beads at 0.9 (1.0 being perfect). This is important from the stand point of contact area between the pipe and bead. With a perfectly round surface the contact area will consistently be the smallest possible area for the bead size. Additionally, in the event these beads invade a zone that is to be produced. Perfectly round beads will not block permeability and render the sand unproductive.

- Thermal Stability: DESI GST™ Beads have a high thermal stability. Temperatures associated with well drilling will not soften or melt DESI GST™ Beads, affecting their structure or shape.

- Cost: Cost roughly half of what the same weight of plastic beads cost.

- Potential Objections

- DESI GST™ Beads could be very abrasive in an air stream or under very high pressure/jet velocity. However, the only real occurrence of high jet velocities is at the bit which is actually a good thing as it is blasting against the bottom of the hole. There have been no reports of premature down hole tool failure or measuring device malfunction attributed to this product.

- Due to the otherwise positive specific gravity characteristic, there have been objections to the use of DESI GST™ Beads because the volume of a 50# bag of DESI GST™ Beads is less than that of a 50# bag of plastic beads.

- Notes

- Could there be validity in using DESI GST™ Bead's in conjunction with Plastic Beads due to the range of specific gravity for both drill string top and bottom lubrication in horizontal drilling?

- Would a PSD be appropriate in this presentation?

- Could it be said that their greater Specific Gravity could contribute to mud weight thus requiring less barite?

- Would a diagram depicting smaller beads preceding larger ones be beneficial (in ref. to screen analysis)?